-

Poland – Polski

-

Lithuania – Lithuanian

-

Netherlands – Dutch

-

Denmark – Danish

-

Estonia – Estonian

-

Finland – Finnish

-

France – French

-

Greece – Greek

-

Italy – Italian

-

Latvia – Latvian

-

Portugal – Portuguese

-

Romania – Romanian

-

Slovenia – Slovenian

-

Spain – Spanish

-

Austria – German

-

Germany – German

-

Switzerland – German

-

Czech Republic– Czech

-

Sweden – Swedish

-

Liechtenstein – German

-

Slovakia – Slovak

-

Ukraine – Ukrainian

-

Moldova – Romanian

-

Cyprus – Greek

-

Ukraine – Russian

-

Croatia – Croatian

-

Bulgaria – Bulgarian

-

Malta – English

This ensures flexible set-up for any conditions, allowing efficient operation even in the most complex projects. Thanks to its reliability and versatility, the system is easier to install and operate, which makes it a convenient solution for many facilities.

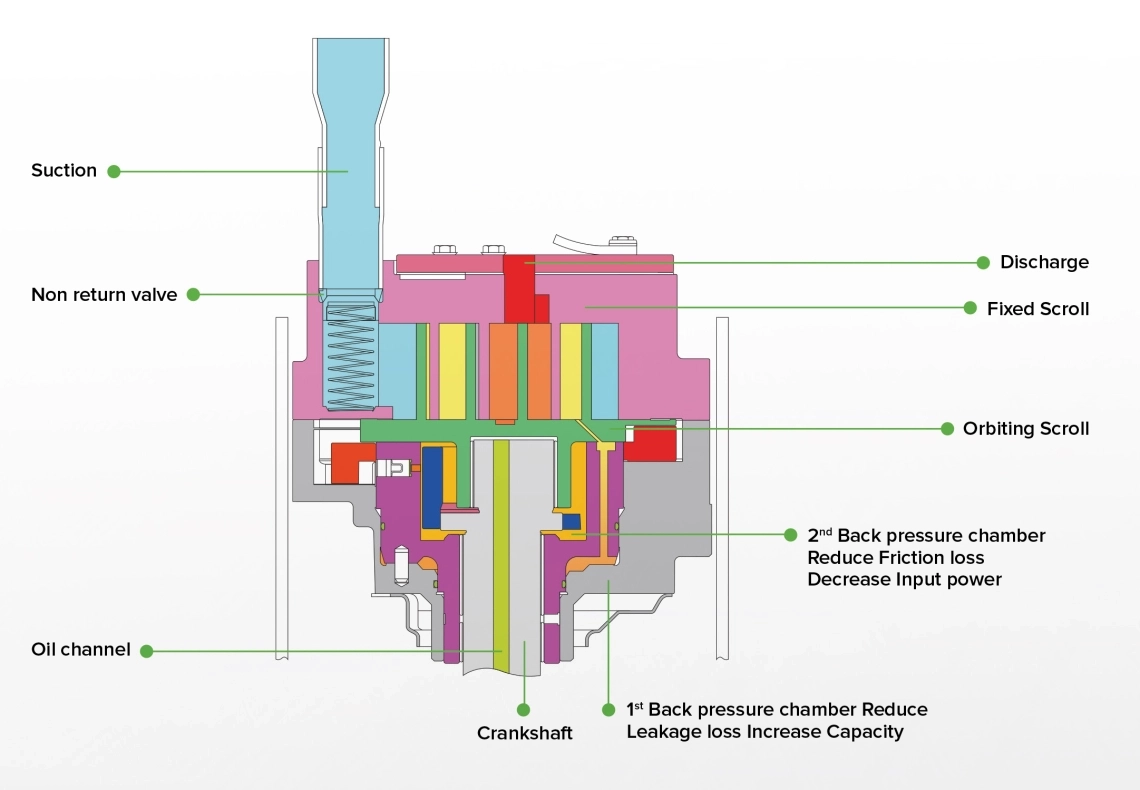

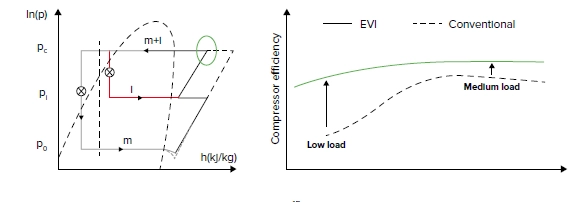

Compressor technologies

The new MRF 7-H series is equipped with a compressor featuring a technology of enhanced vapour injection (EVI) into the compression chamber that increases refrigerant circulation rate by 15% and heating capacity by 30% compared to conventional compressors. An integrated check valve further increases the system efficiency by 5%. During operation in the cooling mode, steady cooling capacity is ensured even at outdoor air temperatures up to +53 °C.

- The compressor scroll is made of softer material, which reduces leakage and mechanical wear compared to conventional scrolls.

- The specially shaped scroll mechanism and pressure relief valve increase stability of the system and efficiency of the compressor.

- А reliable and efficient lubrication system with a high-pressure chamber ensures effective lubrication of all compressor parts along with low oil consumption.

- Integrated design of the frame and casing ensures steady operation of the compressor.

- Three-stage oil distribution system inside the compressor:

- Gravity oil return

- Centrifugal oil separator

- Structural oil separator - The new oil pump design enables the system to operate at high speeds without additional oil consumption, improving lubrication efficiency and reducing friction losses.

Compared to a conventional compressor, the compressor capacity is 27% higher, the COP is 19% higher, and the overall system capacity is 25% higher at -20 °C. The compressor features an integrated check valve, enabling an additional 5% COP improvement during low-speed operation.

Full DC inverter technology

Fast start-up, rapid cooling and heating; smooth start-up, low starting current,

low impact on the power grid; once the room temperature is reached, the compressor automatically switches to low speed with low energy consumption.

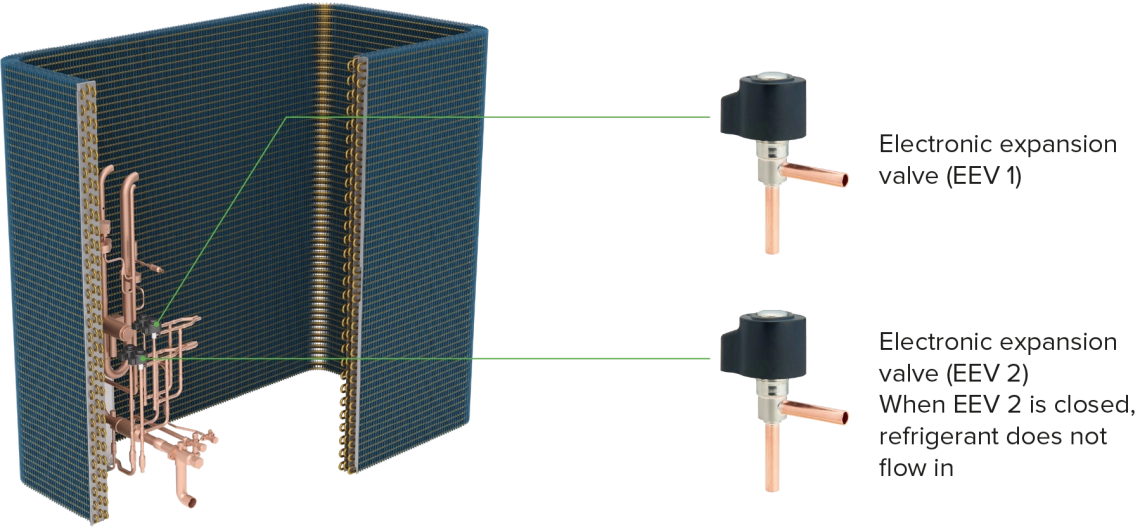

Condenser design with an electronic

expansion valve

Operation of the condenser is controlled by two electronic expansion valves (EEV)

that enable efficient utilization of the heat exchanger surface and distribution of the refrigerant flow according to the thermal load of the indoor units.

Each EEV controls its own section of the condenser so that the surface area of the outdoor heat exchanger matches the indoor load.

Two-stage subcooling technology

The outdoor unit features a two-stage subcooling design with the subcooling level up to 20 °C , significantly increasing both cooling and heating capacity, reducing refrigerant pressure loss in the system, and improving its overall efficiency.

Furthermore, introduction of a subcooling heat exchanger into the system greatly enhances its ability to operate efficiently even with long pipelines, thus ensuring steady performance and improved energy

efficiency.

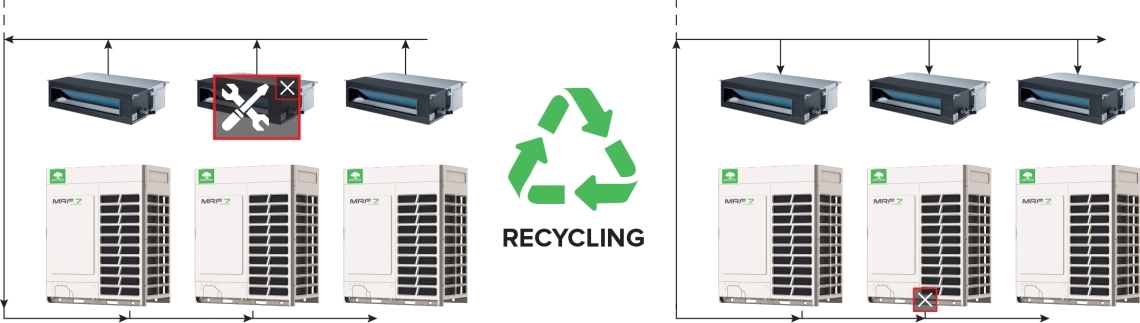

Simplified equipment operation and maintenance

- Wireless connection

Meet the world’s first MRF system with wireless communication between the indoor and outdoor units.

Inter-unit communication routing in the system has become even more convenient. - Deenergized valve control technology

Even if an indoor unit becomes deenergized, the system can use communication wiring to control the EEV.

This enables the faulty indoor unit to be safely shut down without stopping the operation of the entire MRF system.

Automatic refrigerant recovery

If an indoor unit fails, the refrigerant contained therein can be pumped into the outdoor units of the system. If an outdoor unit fails, the refrigerant contained therein can be pumped into the indoor units and the operating outdoor unit. These two types of refrigerant redistribution greatly simplify maintenance and improve efficiency.

Specifications

3-phase/380...400V/50(60)Hz

Single-module: MOH7-08X2EW2AD(L), MOH7-10X2EW2AD(L), MOH7-12X2EW2AD(L)

| Name | Unit | MOH7-08X2EW2AD(L) | MOH7-10X2EW2AD(L) | MOH7-12X2EW2AD(L) | |

| Combination | / | / | / | / | |

|

Cooling |

Rated capacity | kW | 25,2 | 28,0 | 33,5 |

| Rated power consumption | kW | 4,72 | 5,63 | 6,98 | |

| EER1 | / | 5,34 | 4,97 | 4,80 | |

|

Heating |

Rated capacity | kW | 27,0 | 31,5 | 37,5 |

| Rated power consumption | kW | 5,03 | 6,26 | 7,65 | |

| COP1 | / | 5,37 | 5,03 | 4,90 | |

| Power supply | P/V/Hz | 3/380~415/50/60 | 3/380~415/50/60 | 3/380~415/50/60 | |

| Minimum circuit ampacity (MCA) | А | 15,30 | 17,70 | 20,90 | |

| Max. outdoor air flow | m³/h | 11000 | 11000 | 13500 | |

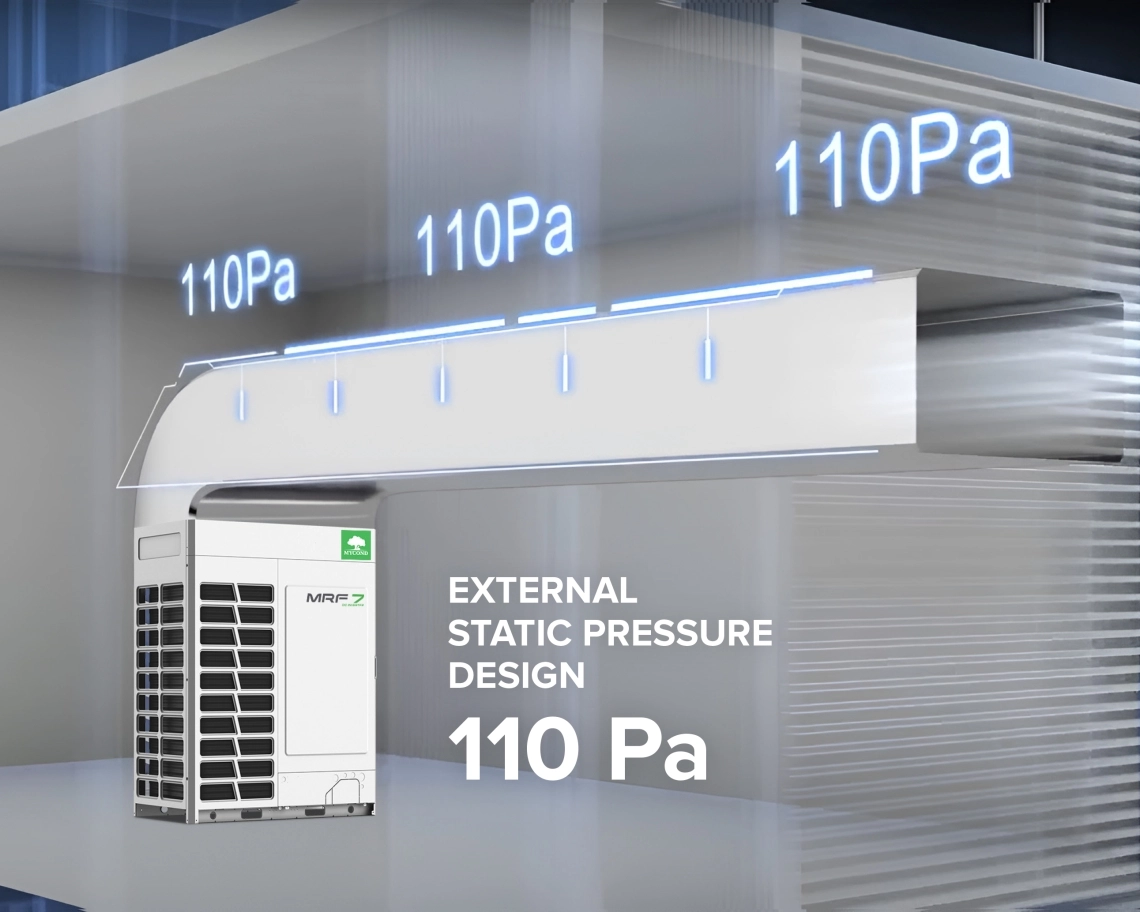

| Max. external static pressure | Pa | 110 | 110 | 110 | |

| Max. outdoor sound pressure level2 | dB(A) | 56 | 57 | 59 | |

| Casing | Colour | / | Light-grey | Light-grey | Light-grey |

|

Compressor |

Brand | / | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC |

| Type | / | Inverter scroll compressor | Inverter scroll compressor | Inverter scroll compressor | |

| Type of compressor oil | / | FVC68D | FVC68D | FVC68D | |

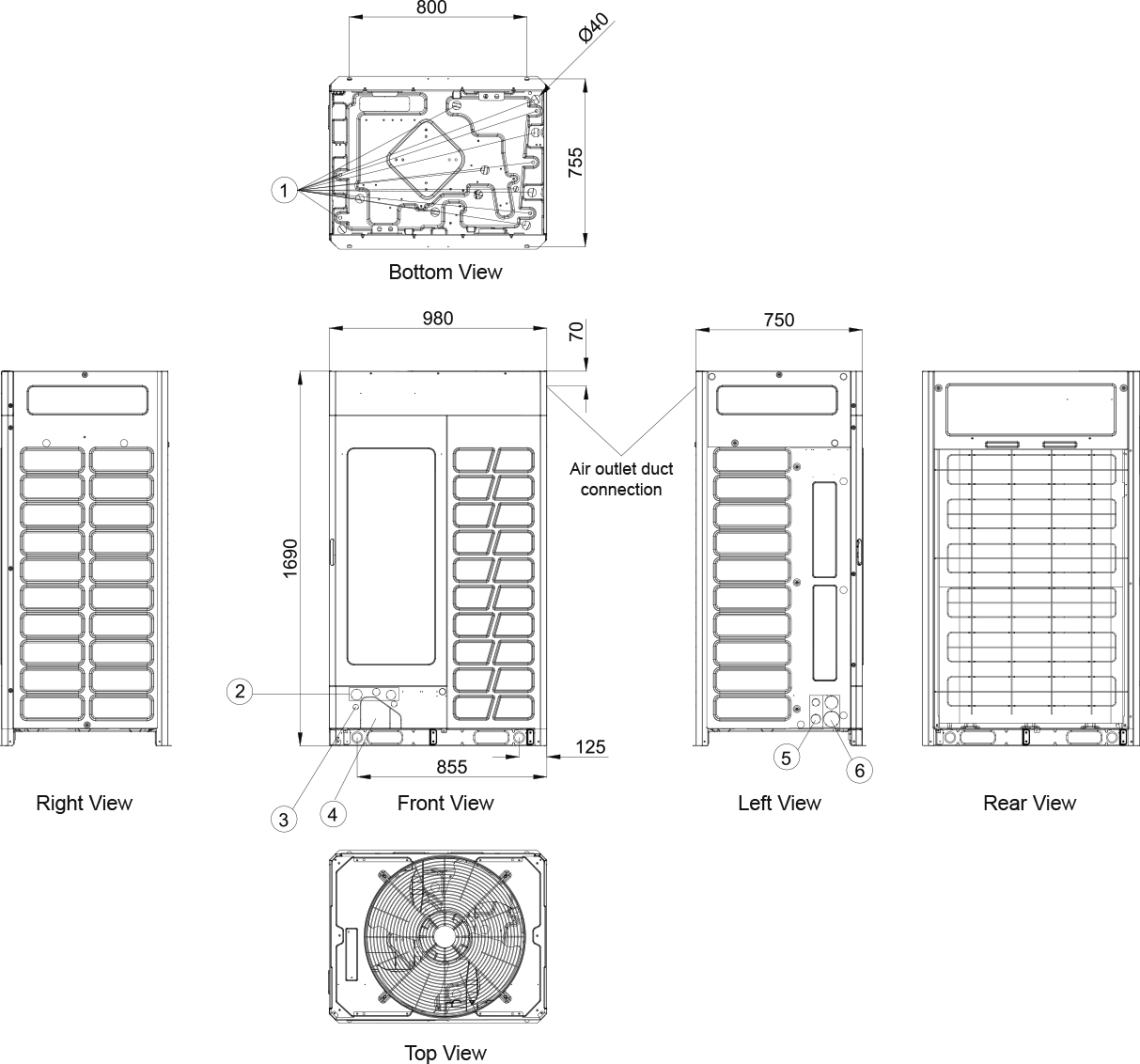

| Dimensions | Net size (W×L×H) | mm | 980×750×1690 | 980×750×1690 | 980×750×1690 |

| Packaging size (W×L×H) | mm | 1070×850×1858 | 1070×850×1858 | 1070×850×1858 | |

| Weight | Net/gross weight | kg | 235/260 | 235/260 | 235/260 |

|

Refrigerant |

Type | / | R410A | R410A | R410A |

| Default refrigerant charge | kg | 9,50 | 9,50 | 9,50 | |

|

Refrigerant |

Outer diameter of liquid pipe | mm | Ø9.52 | Ø9.52 | Ø12.7 |

| Outer diameter of gas pipe | mm | Ø19.05 | Ø22.22 | Ø25.4 | |

| Max. total pipe length | m | 1000 | 1000 | 1000 | |

| Max. pipe length (equivalent/actual) |

m | 260/220 | 260/220 | 260/220 | |

| Max. vertical drop between indoor and outdoor units |

m | 90 (outdoor unit above indoor unit) / 110 (indoor unit above outdoor unit) | |||

| Standard vertical drop between indoor and outdoor units |

m | 50 (outdoor unit above indoor unit) / 40 (indoor unit above outdoor unit) | |||

| Max. vertical drop between indoor units |

m | 30 | 30 | 30 | |

| Standard vertical drop between indoor units |

m | 18 | 18 | 18 | |

| Pipe connection method | / | Gas pipe: soldering / Liquid pipe: flared connection | |||

| Max. length of communication cable between indoor and outdoor units |

m | 1000 | 1000 | 1000 | |

| Ratio of connected indoor units | % | 50...130 (200 with limitations) |

50...130 (200 with limitations) |

50...130 (200 with limitations) |

|

| Max. number of connected indoor units | pcs. | 16(24) | 18(27) | 22(33) | |

| Operating temperature |

Cooling (min ... max) | °C | -10~55 | -10~55 | -10~55 |

| Heating (min ... max) | °C | -25~27 | -25~27 | -25~27 | |

1 Rated conditions:

Indoor temperature (cooling): 27°C DB / 19°C WB, indoor temperature (heating): 20°C DB / 14.5°C WB.

Outdoor temperature (cooling): 35°C DB / 24°C WB, outdoor temperature (heating): 7°C DB / 6°C WB.

2 The data are measured for an equivalent pipe 7.5 m long with a vertical drop of 0 m.

The noise level is measured in the third octave band, in a semi-anechoic chamber using a real-time analyser and a calibrated sound level meter.

This represents the noise level in terms of sound pressure.

3 Use a shielded wire to ensure transmission of control signals from the outdoor unit to the electronic expansion valve of the indoor unit in case the indoor unit

is deenergized. The communication cable diameter must be at least 2×1,5 mm².

The specifications may be changed by the manufacturing plant without prior notice for the purpose of product improvement.

3-phase/380...400V/50(60)Hz

Single-module: MOH7-14X2EW2AD(L), MOH7-16X2EW2AD(L), MOH7-18X2EW2AD(L)

| Name | Unit | MMOH7-14X2EW2AD(L) | MOH7-16X2EW2AD(L) | MOH7-18X2EW2AD(L) | |

| Combination | / | / | / | / | |

|

Cooling |

Rated capacity | kW | 40,0 | 45,0 | 50,4 |

| Rated power consumption | kW | 8,58 | 9,78 | 11,10 | |

| EER1 | / | 4,66 | 4,60 | 4,54 | |

|

Heating |

Rated capacity | kW | 45,0 | 50,0 | 56,5 |

| Rated power consumption | kW | 9,47 | 10,66 | 12,18 | |

| COP1 | / | 4,75 | 4,69 | 4,64 | |

| Power supply | P/V/Hz | 3/380~415/50/60 | 3/380~415/50/60 | 3/380~415/50/60 | |

| Minimum circuit ampacity (MCA) | А | 25,10 | 28,70 | 35,60 | |

| Max. outdoor air flow | m³/h | 13500 | 13500 | 13500 | |

| Max. external static pressure | Pa | 110 | 110 | 110 | |

| Max. outdoor sound pressure level2 | dB(A) | 61 | 61 | 61 | |

| Casing | Colour | / | Light-grey | Light-grey | Light-grey |

|

Compressor |

Brand | / | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC |

| Type | / | Inverter scroll compressor | Inverter scroll compressor | Inverter scroll compressor | |

| Type of compressor oil | / | FVC68D | FVC68D | FVC68D | |

| Dimensions | Net size (W×L×H) | mm | 980×750×1690 | 980×750×1690 | 980×750×1690 |

| Packaging size (W×L×H) | mm | 1070×850×1858 | 1070×850×1858 | 1070×850×1858 | |

| Weight | Net/gross weight | kg | 235/260 | 254/279 | 254/279 |

|

Refrigerant |

Type | / | R410A | R410A | R410A |

| Default refrigerant charge | kg | 9,50 | 12,00 | 12,00 | |

|

Refrigerant |

Outer diameter of liquid pipe | mm | Ø12.7 | Ø12.7 | Ø15.88 |

| Outer diameter of gas pipe | mm | Ø25.4 | Ø28.58 | Ø28.58 | |

| Max. total pipe length | m | 1000 | 1000 | 1000 | |

| Max. pipe length (equivalent/actual) |

m | 260/220 | 260/220 | 260/220 | |

| Max. vertical drop between indoor and outdoor units |

m | 90 (outdoor unit above indoor unit) / 110 (indoor unit above outdoor unit) | |||

| Standard vertical drop between indoor and outdoor units |

m | 50 (outdoor unit above indoor unit) / 40 (indoor unit above outdoor unit) | |||

| Max. vertical drop between indoor units |

m | 30 | 30 | 30 | |

| Standard vertical drop between indoor units |

m | 18 | 18 | 18 | |

| Pipe connection method | / | Gas pipe: soldering / Liquid pipe: flared connection | |||

| Max. length of communication cable between indoor and outdoor units |

m | 1000 | 1000 | 1000 | |

| Ratio of connected indoor units | % | 50...130 (200 with limitations) |

50...130 (200 with limitations) |

50...130 (200 with limitations) |

|

| Max. number of connected indoor units | pcs. | 26(40) | 30(46) | 33(50) | |

| Operating temperature |

Cooling (min ... max) | °C | -10~55 | -10~55 | -10~55 |

| Heating (min ... max) | °C | -25~27 | -25~27 | -25~27 | |

1 Rated conditions:

Indoor temperature (cooling): 27°C DB / 19°C WB, indoor temperature (heating): 20°C DB / 14.5°C WB.

Outdoor temperature (cooling): 35°C DB / 24°C WB, outdoor temperature (heating): 7°C DB / 6°C WB.

2 The data are measured for an equivalent pipe 7.5 m long with a vertical drop of 0 m.

The noise level is measured in the third octave band, in a semi-anechoic chamber using a real-time analyser and a calibrated sound level meter.

This represents the noise level in terms of sound pressure.

3 Use a shielded wire to ensure transmission of control signals from the outdoor unit to the electronic expansion valve of the indoor unit in case the indoor unit

is deenergized. The communication cable diameter must be at least 2×1,5 mm².

The specifications may be changed by the manufacturing plant without prior notice for the purpose of product improvement.

3-phase/380...400V/50(60)Hz

Single-module: MOH7-20X2EW2AD(L), MOH7-22X2EW2AD(L), MOH7-24X2EW2AD(L)

| Name | Unit | MOH7-20X2EW2AD(L) | MOH7-22X2EW2AD(L) | MOH7-24X2EW2AD(L) | |

| Combination | / | / | / | / | |

|

Cooling |

Rated capacity | kW | 56,0 | 61,5 | 68,0 |

| Rated power consumption | kW | 12,53 | 14,40 | 16,08 | |

| EER1 | / | 4,47 | 4,27 | 4,23 | |

|

Heating |

Rated capacity | kW | 63,0 | 69,0 | 75,0 |

| Rated power consumption | kW | 13,70 | 15,83 | 17,56 | |

| COP1 | / | 4,60 | 4,36 | 4,27 | |

| Power supply | P/V/Hz | 3/380~415/50/60 | 3/380~415/50/60 | 3/380~415/50/60 | |

| Minimum circuit ampacity (MCA) | А | 36,40 | 39,20 | 41,80 | |

| Max. outdoor air flow | m³/h | 17000 | 18000 | 18000 | |

| Max. external static pressure | Pa | 110 | 110 | 110 | |

| Max. outdoor sound pressure level2 | dB(A) | 62 | 62 | 62 | |

| Casing | Colour | / | Light-grey | Light-grey | Light-grey |

|

Compressor |

Brand | / | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC |

| Type | / | Inverter scroll compressor | Inverter scroll compressor | Inverter scroll compressor | |

| Type of compressor oil | / | FVC68D | FVC68D | FVC68D | |

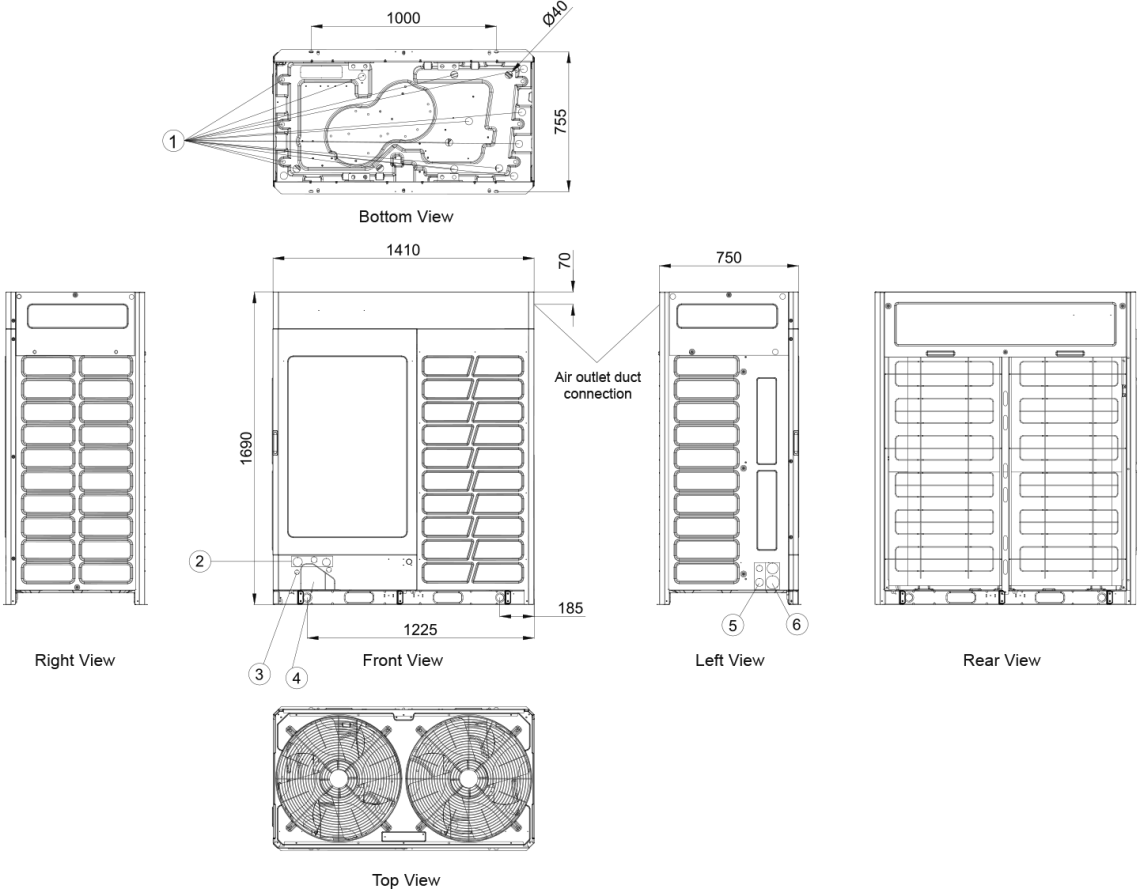

| Dimensions | Net size (W×L×H) | mm | 1410×750×1690 | 1410×750×1690 | 1410×750×1690 |

| Packaging size (W×L×H) | mm | 1475×850×1858 | 1475×850×1858 | 1475×850×1858 | |

| Weight | Net/gross weight | kg | 359 / 388 | 359 / 388 | 359 / 388 |

|

Refrigerant |

Type | / | R410A | R410A | R410A |

| Default refrigerant charge | kg | 13,00 | 13,00 | 13,00 | |

|

Refrigerant |

Outer diameter of liquid pipe | mm | Ø15.88 | Ø15.88 | Ø15.88 |

| Outer diameter of gas pipe | mm | Ø28.58 | Ø28.58 | Ø28.58 | |

| Max. total pipe length | m | 1000 | 1000 | 1000 | |

| Max. pipe length (equivalent/actual) |

m | 260/220 | 260/220 | 260/220 | |

| Max. vertical drop between indoor and outdoor units |

m | 90 (outdoor unit above indoor unit) / 110 (indoor unit above outdoor unit) | |||

| Standard vertical drop between indoor and outdoor units |

m | 50 (outdoor unit above indoor unit) / 40 (indoor unit above outdoor unit) | |||

| Max. vertical drop between indoor units |

m | 30 | 30 | 30 | |

| Standard vertical drop between indoor units |

m | 18 | 18 | 18 | |

| Pipe connection method | / | Gas pipe: soldering / Liquid pipe: flared connection | |||

| Max. length of communication cable between indoor and outdoor units |

m | 1000 | 1000 | 1000 | |

| Ratio of connected indoor units | % | 50...130 (200 with limitations) |

50...130 (200 with limitations) |

50...130 (200 with limitations) |

|

| Max. number of connected indoor units | pcs. | 37(56) | 41(63) | 45(64) | |

| Operating temperature |

Cooling (min ... max) | °C | -10~55 | -10~55 | -10~55 |

| Heating (min ... max) | °C | -25~27 | -25~27 | -25~27 | |

1 Rated conditions:

Indoor temperature (cooling): 27°C DB / 19°C WB, indoor temperature (heating): 20°C DB / 14.5°C WB.

Outdoor temperature (cooling): 35°C DB / 24°C WB, outdoor temperature (heating): 7°C DB / 6°C WB.

2 The data are measured for an equivalent pipe 7.5 m long with a vertical drop of 0 m.

The noise level is measured in the third octave band, in a semi-anechoic chamber using a real-time analyser and a calibrated sound level meter.

This represents the noise level in terms of sound pressure.

3 Use a shielded wire to ensure transmission of control signals from the outdoor unit to the electronic expansion valve of the indoor unit in case the indoor unit

is deenergized. The communication cable diameter must be at least 2×1,5 mm².

The specifications may be changed by the manufacturing plant without prior notice for the purpose of product improvement.

3-phase/380...400V/50(60)Hz

Single-module: MOH7-26X2EW2AD(L), MOH7-28X2EW2AD(L), MOH7-30X2EW2AD(L)

| Name | Unit | MOH7-26X2EW2AD(L) | MOH7-28X2EW2AD(L) | MOH7-30X2EW2AD(L) | |

| Combination | / | / | / | / | |

|

Cooling |

Rated capacity | kW | 73,5 | 80,0 | 85,0 |

| Rated power consumption | kW | 18,51 | 20,59 | 22,69 | |

| EER1 | / | 3,97 | 3,89 | 3,75 | |

|

Heating |

Rated capacity | kW | 82,5 | 90,0 | 95,0 |

| Rated power consumption | kW | 20,37 | 22,78 | 25,07 | |

| COP1 | / | 4,05 | 3,95 | 3,79 | |

| Power supply | P/V/Hz | 3/380~415/50/60 | 3/380~415/50/60 | 3/380~415/50/60 | |

| Minimum circuit ampacity (MCA) | А | 42,80 | 44,60 | 48,60 | |

| Max. outdoor air flow | m³/h | 19000 | 19000 | 26000 | |

| Max. external static pressure | Pa | 110 | 110 | 110 | |

| Max. outdoor sound pressure level2 | dB(A) | 63 | 63 | 64 | |

| Casing | Colour | / | Light-grey | Light-grey | Light-grey |

|

Compressor |

Brand | / | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC |

| Type | / | Inverter scroll compressor | Inverter scroll compressor | Inverter scroll compressor | |

| Type of compressor oil | / | FVC68D | FVC68D | FVC68D | |

| Dimensions | Net size (W×L×H) | mm | 1410×750×1690 | 1410×750×1690 | 1785×830×1858 |

| Packaging size (W×L×H) | mm | 1475×850×1858 | 1475×850×1858 | 1886×930×2025 | |

| Weight | Net/gross weight | kg | 382 / 411 | 382 / 411 | 431 / 473 |

|

Refrigerant |

Type | / | R410A | R410A | R410A |

| Default refrigerant charge | kg | 16,00 | 16,00 | 18,00 | |

|

Refrigerant |

Outer diameter of liquid pipe | mm | Ø15.88 | Ø19.05 | Ø19.05 |

| Outer diameter of gas pipe | mm | Ø28.58 | Ø31.8 | Ø31.8 | |

| Max. total pipe length | m | 1000 | 1000 | 1000 | |

| Max. pipe length (equivalent/actual) |

m | 260/220 | 260/220 | 260/220 | |

| Max. vertical drop between indoor and outdoor units |

m | 90 (outdoor unit above indoor unit) / 110 (indoor unit above outdoor unit) | |||

| Standard vertical drop between indoor and outdoor units |

m | 50 (outdoor unit above indoor unit) / 40 (indoor unit above outdoor unit) | |||

| Max. vertical drop between indoor units |

m | 30 | 30 | 30 | |

| Standard vertical drop between indoor units |

m | 18 | 18 | 18 | |

| Pipe connection method | / | Gas pipe: soldering / Liquid pipe: flared connection | |||

| Max. length of communication cable between indoor and outdoor units |

m | 1000 | 1000 | 1000 | |

| Ratio of connected indoor units | % | 50...130 (200 with limitations) |

50...130 (200 with limitations) |

50...130 (200 with limitations) |

|

| Max. number of connected indoor units | pcs. | 49(64) | 53(64) | 56(64) | |

| Operating temperature |

Cooling (min ... max) | °C | -10~55 | -10~55 | -10~55 |

| Heating (min ... max) | °C | -25~27 | -25~27 | -25~27 | |

1 Rated conditions:

Indoor temperature (cooling): 27°C DB / 19°C WB, indoor temperature (heating): 20°C DB / 14.5°C WB.

Outdoor temperature (cooling): 35°C DB / 24°C WB, outdoor temperature (heating): 7°C DB / 6°C WB.

2 The data are measured for an equivalent pipe 7.5 m long with a vertical drop of 0 m.

The noise level is measured in the third octave band, in a semi-anechoic chamber using a real-time analyser and a calibrated sound level meter.

This represents the noise level in terms of sound pressure.

3 Use a shielded wire to ensure transmission of control signals from the outdoor unit to the electronic expansion valve of the indoor unit in case the indoor unit

is deenergized. The communication cable diameter must be at least 2×1,5 mm².

The specifications may be changed by the manufacturing plant without prior notice for the purpose of product improvement.

3-phase/380...400 V/50(60)Hz

Single-module: MOH7-32X2EW2AD(L), MOH7-34X2EW2AD(L)

| Name | Unit | MOH7-32X2EW2AD(L) | MOH7-34X2EW2AD(L) | |

| Combination | / | / | / | |

|

Cooling |

Rated capacity | kW | 90,0 | 95,0 |

| Rated power consumption | kW | 25,03 | 26,58 | |

| EER1 | / | 3,60 | 3,57 | |

|

Heating |

Rated capacity | kW | 100,0 | 106,5 |

| Rated power consumption | kW | 27,51 | 29,46 | |

| COP1 | / | 3,64 | 3,61 | |

| Power supply | P/V/Hz | 3/380~415/50/60 | 3/380~415/50/60 | |

| Minimum circuit ampacity (MCA) | А | 51,60 | 54,70 | |

| Max. outdoor air flow | m³/h | 26000 | 27000 | |

| Max. external static pressure | Pa | 110 | 110 | |

| Max. outdoor sound pressure level2 | dB(A) | 64 | 66 | |

| Casing | Colour | / | Light-grey | Light-grey |

|

Compressor |

Brand | / | MITSUBISHI ELECTRIC | MITSUBISHI ELECTRIC |

| Type | / | Inverter scroll compressor | Inverter scroll compressor | |

| Type of compressor oil | / | FVC68D | FVC68D | |

| Dimensions | Net size (W×L×H) | mm | 1785×830×1858 | 1785×830×1858 |

| Packaging size (W×L×H) | mm | 1886×930×2025 | 1886×930×2025 | |

| Weight | Net/gross weight | kg | 431 / 473 | 460 / 502 |

|

Refrigerant |

Type | / | R410A | R410A |

| Default refrigerant charge | kg | 18,00 | 21,00 | |

|

Refrigerant |

Outer diameter of liquid pipe | mm | Ø19.05 | Ø19.05 |

| Outer diameter of gas pipe | mm | Ø31.8 | Ø31.8 | |

| Max. total pipe length | m | 1000 | 1000 | |

| Max. pipe length (equivalent/actual) |

m | 260/220 | 260/220 | |

| Max. vertical drop between indoor and outdoor units |

m | 90 (outdoor unit above indoor unit) / 110 (indoor unit above outdoor unit) | ||

| Standard vertical drop between indoor and outdoor units |

m | 50 (outdoor unit above indoor unit) / 40 (indoor unit above outdoor unit) | ||

| Max. vertical drop between indoor units |

m | 30 | 30 | |

| Standard vertical drop between indoor units |

m | 18 | 18 | |

| Pipe connection method | / | Gas pipe: soldering / Liquid pipe: flared connection | ||

| Max. length of communication cable between indoor and outdoor units |

m | 1000 | 1000 | |

| Ratio of connected indoor units | % | 50...130 (200 with limitations) |

50...130 (200 with limitations) |

|

| Max. number of connected indoor units | pcs. | 60(64) | 63(64) | |

| Operating temperature |

Cooling (min ... max) | °C | -10~55 | -10~55 |

| Heating (min ... max) | °C | -25~27 | -25~27 | |

1 Rated conditions:

Indoor temperature (cooling): 27°C DB / 19°C WB, indoor temperature (heating): 20°C DB / 14.5°C WB.

Outdoor temperature (cooling): 35°C DB / 24°C WB, outdoor temperature (heating): 7°C DB / 6°C WB.

2 The data are measured for an equivalent pipe 7.5 m long with a vertical drop of 0 m.

The noise level is measured in the third octave band, in a semi-anechoic chamber using a real-time analyser and a calibrated sound level meter.

This represents the noise level in terms of sound pressure.

3 Use a shielded wire to ensure transmission of control signals from the outdoor unit to the electronic expansion valve of the indoor unit in case the indoor unit

is deenergized. The communication cable diameter must be at least 2×1,5 mm².

The specifications may be changed by the manufacturing plant without prior notice for the purpose of product improvement.

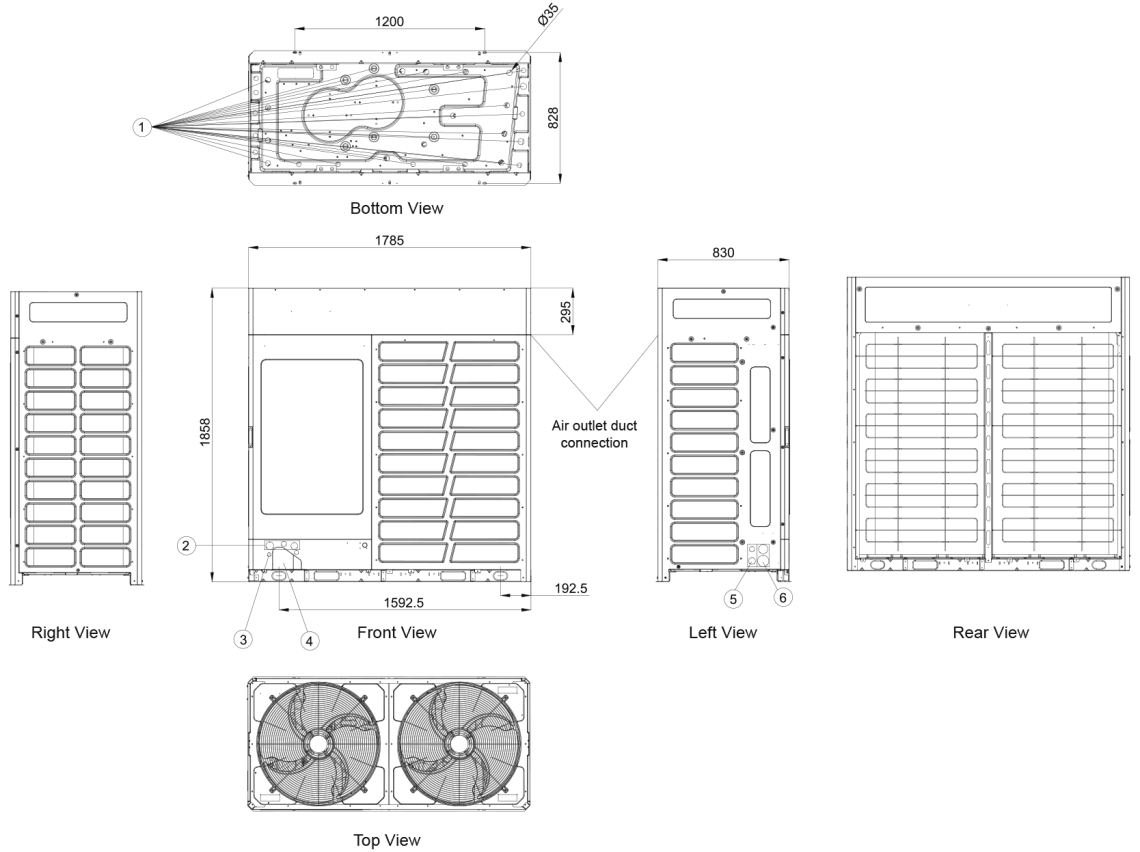

Dimensions

MOH7-08X2EW2AD(L), MOH7-10X2EW2AD(L), MOH7-12X2EW2AD(L), MOH7-14X2EW2AD(L), MOH7-16X2EW2AD(L), MOH7-18X2EW2AD(L)

MOH7-20X2EW2AD(L), MOH7-22X2EW2AD(L), MOH7-24X2EW2AD(L), MOH7-26X2EW2AD(L), MOH7-28X2EW2AD(L)

MOH7-08X2EW2AD(L), MOH7-10X2EW2AD(L), MOH7-12X2EW2AD(L), MOH7-14X2EW2AD(L), MOH7-16X2EW2AD(L), MOH7-18X2EW2AD(L)