Pool owners often worry: can mold develop inside a dehumidifier? This concern is justified, as a dehumidifier constantly works with humid air, creating a potentially favorable environment for fungal growth. Especially considering that mold is not only unpleasant but also dangerous to health — its spores spread through the air and can cause allergic reactions and respiratory problems.

Let’s be honest: yes, mold can indeed appear in poorly maintained units. However, MSHA(C) dehumidifiers are designed with this threat in mind and feature multiple layers of protection. With proper maintenance, the risk of mold is minimal. In this article, we’ll look at where exactly mold can appear inside a dehumidifier, why MSHA(C) models are more resistant to this issue due to their design features, and provide a practical maintenance guide to help prevent any problems.

Can mold develop in a dehumidifier?

The honest answer: yes, mold can develop in any dehumidifier if maintenance rules aren’t followed. Mold is a fungus that requires specific conditions to grow: humidity above 70%, temperature of 15–30°C, an organic surface to adhere to, and stagnant air. A pool dehumidifier works precisely with humid air and contains several zones where such conditions can potentially arise.

The most vulnerable areas in a dehumidifier are:

- Filters — they collect dust and organic particles from the air while constantly contacting humid air, creating an ideal environment for mold reproduction.

- Condensate pan — if water stagnates due to a clogged drain, bacteria and mold can start developing in the pan.

- Heat exchanger — during operation, moisture condenses on it, and if it doesn’t dry properly after shutdown, mold can begin growing on its surface.

- Ductwork — if condensate forms inside and there’s insufficient air circulation, mold may appear.

Factors that increase the risk of mold in a dehumidifier:

- Infrequent maintenance: filters aren’t cleaned for months.

- Drainage issues: water stagnates in the pan.

- Prolonged shutdown of the dehumidifier without prior drying.

- Dirty filters that trap more organic particles.

- Lack of UV sterilization, which helps destroy spores and bacteria.

Conversely, factors that reduce the risk of mold:

- Regular filter cleaning every 2–4 weeks.

- Effective drainage where water doesn’t remain in the system.

- Continuous operation of the dehumidifier to dry internal elements.

- Using HEPA filters and UV lamps that trap and destroy mold spores.

The consequences of mold in a dehumidifier can be serious: mold spores spread throughout the pool area, a musty odor appears, the risk of allergic reactions and respiratory problems for users increases, the dehumidifier’s performance drops due to clogged filters, and corrosion can begin developing on the heat exchanger.

Why MSHA(C) units resist mold: design solutions

MSHA(C) X series dehumidifiers have six layers of mold protection that make them particularly resistant to fungal and bacterial growth. Let’s look at each of them in detail.

1. Positive-pressure drainage

In MSHA(C) models, the condensate pan is optimally positioned relative to the airflow direction. As a result, the pressure generated by the supply air is used as an additional force that pushes water into the drainage system. This engineering solution provides several important benefits:

- Water doesn’t stagnate in the pan and is immediately routed to the drain.

- The pan dries quickly after the dehumidifier stops.

- No standing water means no conditions for mold and bacteria to develop.

Unlike conventional dehumidifiers where the pan is at the bottom and water drains by gravity (which often leads to stagnation), MSHA(C) removes water more efficiently, significantly reducing the risk of mold and unpleasant odors.

2. SUS304 stainless steel

The condensate pan in MSHA(C) is made of medical-grade SUS304 stainless steel. This is extremely important because:

- This material does not corrode, even with constant contact with moisture.

- The smooth stainless-steel surface has no micropores or cracks, depriving mold of places to anchor.

- The surface is easy to clean during maintenance.

Compared to dehumidifiers that use plastic pans (which can become rough and porous over time) or galvanized steel (prone to rust), SUS304 stainless steel provides long-term protection against mold growth.

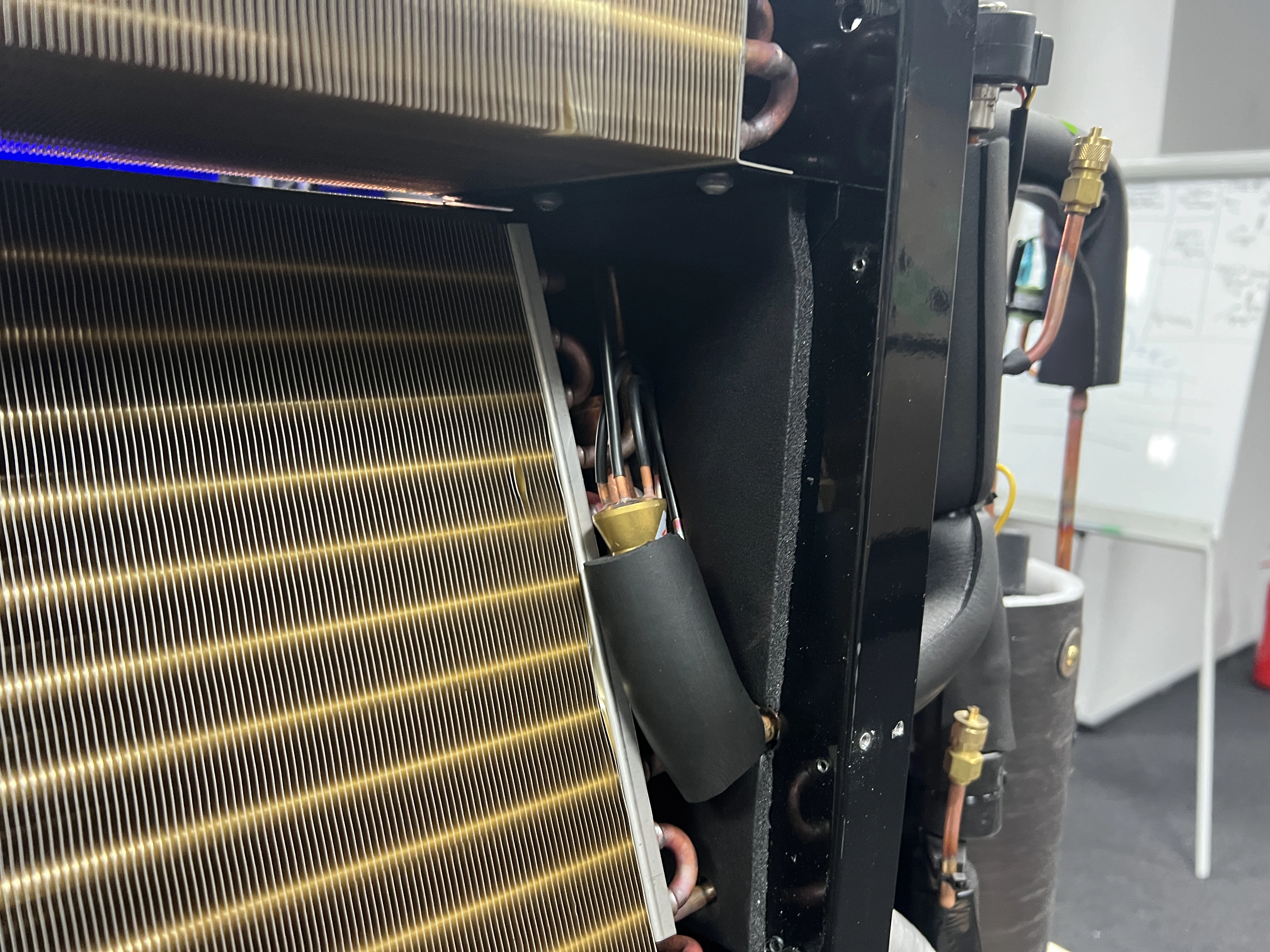

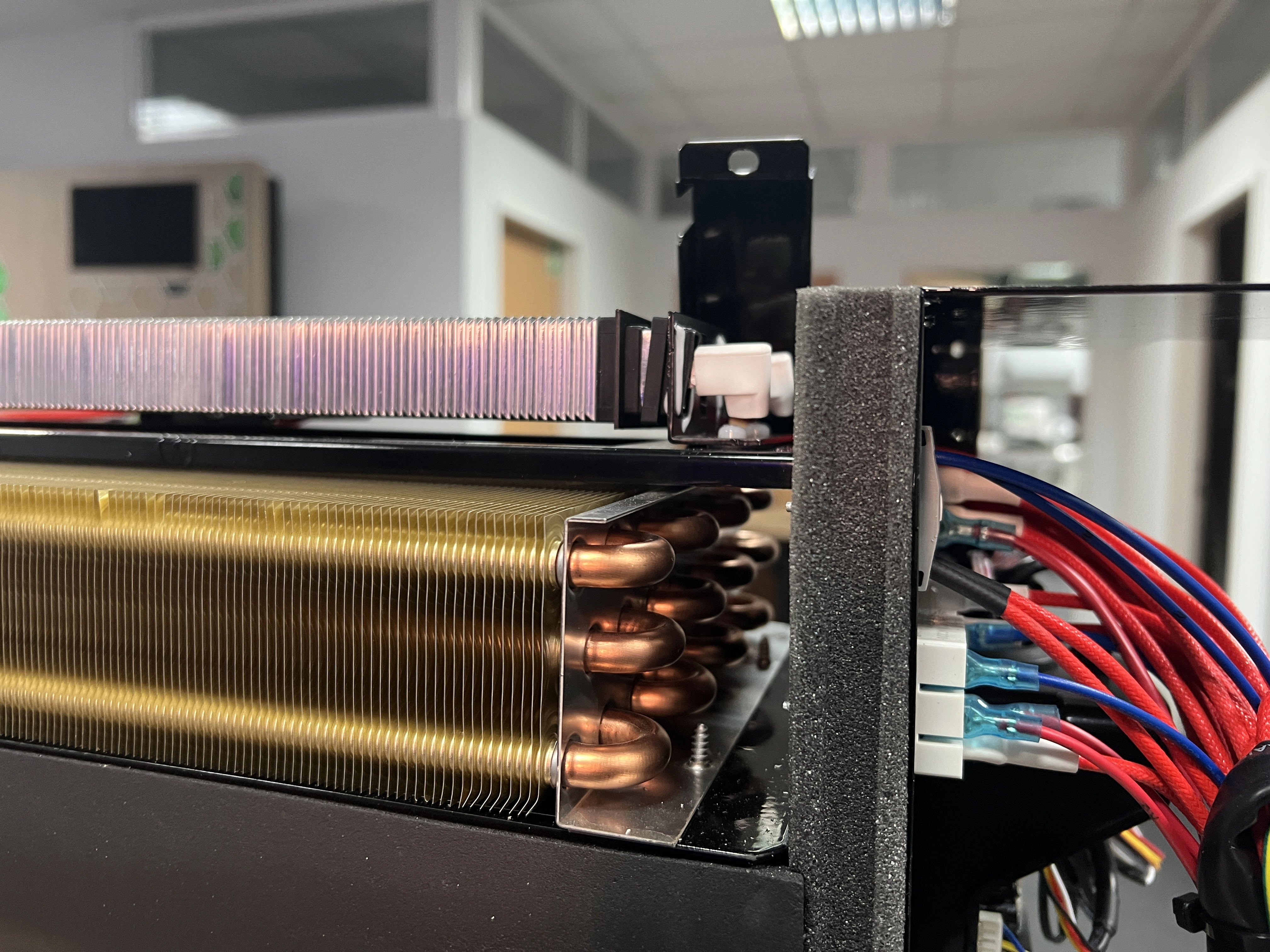

3. Hydrophobic Blue Coating on the heat exchanger

The heat exchangers in MSHA(C) dehumidifiers are treated with a special hydrophobic Blue Coating that:

- Repels water, preventing it from lingering on the heat exchanger fins.

- Speeds up drying of the heat exchanger after shutdown.

- Creates conditions where mold finds it harder to adhere and start growing.

This coating significantly extends the service life of the heat exchanger and improves the overall hygiene of the dehumidifier.

4. Three-stage filtration to trap spores

The filtration system in MSHA(C) dehumidifiers is designed to effectively capture all types of pollutants, including mold spores:

- G4 filter traps large particles, dust, hair, and other contaminants.

- F7 filter captures medium particles, including mold spores, and has a filtration efficiency of 97% for PM2.5 particles.

- HEPA H13 filter (option) provides the highest level of filtration — up to 99.5% of spores, bacteria, and viruses.

Thanks to this multi-layer filtration system, mold spores do not penetrate deep into the dehumidifier and do not settle on the heat exchanger or in the pan, which significantly reduces the risk of mold inside the unit.

5. UV lamp to destroy spores

As an additional option, MSHA(C) dehumidifiers can be equipped with a UV-C lamp installed before the HEPA filter. This lamp:

- Sterilizes the air by killing bacteria, viruses, and mold spores.

- Prevents spores from germinating, even if they get inside the system.

- Is especially important for commercial facilities and regions with high humidity.

The UV lamp acts as extra insurance against mold growth, especially for those who can’t provide very regular dehumidifier maintenance.

6. Continuous air circulation and drying

If the MSHA(C) dehumidifier runs 24/7 (recommended for pool spaces), the continuous airflow through all system elements ensures:

- Drying of internal surfaces.

- No stagnant, humid zones where mold could develop.

- Maintenance of an optimal indoor microclimate.

Even if the dehumidifier is turned off for a short time, internal components dry out thanks to the specific design and materials.

Thanks to these six levels of protection, MSHA(C) dehumidifiers show high resistance to mold development. With proper maintenance, the risk of fungi and bacteria is minimal, ensuring clean, healthy air in your pool area.

Proper MSHA(C) maintenance: a practical guide

Despite all the design advantages of MSHA(C) dehumidifiers, regular maintenance remains the key factor in preventing mold and maintaining efficient operation. Let’s review the most important aspects of proper care.

Filter cleaning: the most important maintenance task

Filter cleaning frequency:

- G4 filter (coarse) — every 2–4 weeks

- F7 filter (fine) — every 1–2 months

- HEPA H13 filter — check every 6–12 months, replace every 2 years

The frequency may vary depending on air cleanliness (if the room is dusty, clean more often), pool usage intensity, and the season (there is more dust and pollen in spring and summer).

How to clean filters correctly:

- G4 filter: remove it from the dehumidifier (it’s usually fixed with latches), vacuum or rinse with warm water without detergents, dry completely for 24 hours, and reinstall.

- F7 filter: carefully remove and vacuum. If the filter is very dirty, you can gently rinse it (though this is usually not recommended), dry thoroughly, and reinstall.

- HEPA H13 filter: do not wash, as this will damage the fine-fiber structure. You can gently vacuum from the clean side, but typically these filters are simply replaced with new ones every 1–2 years.

Signs it’s time to clean the filters:

- Reduced dehumidifier performance (humidity does not drop to the desired level)

- Increased noise level (the compressor works harder)

- Appearance of a musty odor

- Visible filter contamination (if they’re accessible for inspection)

Drainage check

It is recommended to check the drainage system at least once a month:

What to check:

- Whether water flows freely from the drain pipe

- No standing water in the pan

- No blockages in the pipe

How to check drainage:

- Turn on the dehumidifier for 30–60 minutes.

- Check the drain outlet — water should be flowing (assuming the room humidity is high enough).

If water isn’t draining, possible causes are: a clogged drain (needs cleaning), incorrect drain pipe slope (needs correction), or a system malfunction (call service).

The water trap also requires attention — it is recommended to flush it every 3–6 months, as it can silt up, which will lead to unpleasant odors.

Visual inspection of the heat exchanger

Every 6 months, it is advisable to visually inspect the heat exchanger (if this is possible without disassembling the unit):

- Check for contaminants on the heat exchanger fins.

- Ensure there is no corrosion or rust.

- Inspect for any mold growth.

If the heat exchanger is clean, you can continue operation. If contamination is found, professional cleaning is required, which should be performed by a service team using special agents and equipment. Heat exchanger cleaning is usually performed every 1–2 years, depending on operating conditions, and helps restore the dehumidifier’s performance.

Checking the UV lamp

If your dehumidifier is equipped with a UV lamp, it should be checked once a year:

- The UV lamp’s service life is approximately 8,000–10,000 operating hours.

- With 24/7 operation, that’s roughly one year.

You can check the lamp condition visually through a viewing window (if provided by the design) or via the hour counter in the controller. The UV lamp should be replaced by a service team once a year under continuous operation.

General system check

Annual maintenance should be performed by a service team. It includes:

- Checking and cleaning all filters

- Heat exchanger cleaning (if necessary)

- Drainage system inspection

- UV lamp replacement (if installed)

- Refrigerant circuit leak check

- Diagnostics of the compressor and fans

- Automation and sensor checks

- Ductwork inspection (if accessible)

It’s important to understand that annual maintenance significantly extends the dehumidifier’s service life — up to 15+ years, while without regular maintenance issues can start appearing after just 3–5 years of operation.

Signs of trouble: when you need unscheduled cleaning or service

Sometimes the dehumidifier may signal problems that require immediate action, without waiting for scheduled maintenance. Here are the main signs and symptoms to look out for.

Odor from the dehumidifier

An unpleasant smell is one of the earliest indicators of problems. Possible causes:

- Mold in the filters — immediate cleaning or replacement is required

- Standing water in the pan — the drainage should be checked

- Mold on the heat exchanger — professional cleaning is required

- Dirty water trap — needs flushing

Recommended actions: first clean the filters and check the drainage. If the odor persists, call a service team for diagnostics and heat exchanger cleaning.

Performance drop

If the dehumidifier isn’t doing its job, it may present the following symptoms:

- Humidity in the room does not drop to the comfortable 55–60% level

- The dehumidifier runs constantly without cycling off

- Air at the outlet isn’t as warm as usual

Most common causes:

- Clogged filters (90% of cases) — cleaning required

- Dirty heat exchanger — service required

- Refrigerant leak — service required

- Incorrect settings — check parameters

Increased noise

The normal noise level for MSHA(C) dehumidifiers is 35–55 dB, depending on the model. If the unit has become louder, possible causes include:

- Clogged filters — the compressor runs under increased load

- Vibration due to loosened fasteners — needs tightening

- Fan bearing wear — service required

Water dripping outside the drain

If you notice leakage, it may be due to:

- Pan overflow due to a clogged drain — clean it

- Crack in the pan — replacement required (a rare issue for MSHA(C) with stainless pan)

- Leaky connection — tighten it

The dehumidifier won’t start

If the device doesn’t start, check:

- Power supply availability (a protection breaker might have tripped)

- Safety shutdown (due to overheating or overflow)

- Humidity sensor (may be faulty)

If a basic check doesn’t help, call a service team.

Common operating mistakes that lead to problems

Even the most reliable equipment can fail if used improperly. Here are seven of the most common mistakes MSHA(C) dehumidifier owners make and their consequences.

Mistake #1: “I’ll clean the filter someday”

Consequences: Clogged filters lead to a 30–50% performance drop; the compressor runs overloaded, reducing the dehumidifier’s service life from 10+ years to 2–3 years.

Correct actions: Clean the G4 filter every 2–4 weeks. Set a reminder on your phone or calendar.

Mistake #2: “I’ll wash the filter and put it back in right away”

Consequences: A wet filter creates an ideal environment for mold growth. A bad smell can appear in just a week.

Correct actions: After rinsing, the filter must be completely air-dried for 24 hours before reinstalling in the dehumidifier.

Mistake #3: “I’ll turn the dehumidifier off for the winter”

Consequences: Residual moisture inside the unit can lead to mold formation over several months.

Correct actions: Before a long shutdown, run ventilation mode without cooling for 2–3 hours to dry it out or, if possible, leave it running at minimum power.

Mistake #4: “The drain sort of works, that’s enough”

Consequences: A partial clog leads to standing water in the pan, creating conditions for mold and odors.

Correct actions: Check the drain monthly. Water must flow freely.

Mistake #5: “The UV lamp burned out a year ago, but that’s not critical”

Consequences: Lack of air sterilization allows mold spores to circulate freely indoors.

Correct actions: Replace the UV lamp annually if it runs 24/7.

Mistake #6: “Service is expensive; I’ll skip it”

Consequences: The heat exchanger becomes dirty, performance drops by 30–50%. The extra electricity cost due to inefficient operation often exceeds the cost of service.

Correct actions: Annual maintenance pays for itself through energy savings and extended equipment life.

Mistake #7: “Install and forget”

Consequences: After 2–3 years — a whole set of issues: odor, low performance, possible mold formation.

Correct actions: A dehumidifier, like a car, needs regular maintenance. It is simple, but essential.

Maintenance specifics for different conditions

Depending on operating conditions and the type of facility, the approach to maintaining MSHA(C) dehumidifiers may differ. Let’s consider four typical scenarios.

Commercial facilities with heavy use

Specifics:

- Filters get dirty faster due to higher visitor traffic

- Greater responsibility to clients for air quality

- More intensive equipment operation

Recommendations:

- Clean G4 filters every 1–2 weeks

- UV lamp is mandatory

- HEPA H13 filter is desirable

- Keep a maintenance log

- Assign a person responsible for maintenance

- Service contract for annual maintenance and emergency callouts

Residential pools with moderate use

Specifics:

- Lower intensity of use

- Maintenance can be performed by the owner

- Lower risk of air contamination

Recommendations:

- Clean G4 filters every 2–4 weeks

- UV lamp is desirable but not mandatory

- Simple owner’s guide for filter cleaning

- Calendar reminders for maintenance

- Professional service every 1–2 years

High-humidity regions

Specifics:

- The dehumidifier runs more intensively

- More condensate is generated

- Higher load on the drainage system

- Increased risk of mold development

Recommendations:

- HEPA H13 filter and UV lamp are mandatory

- Drainage check every 2 weeks

- Annual service is mandatory

- Monitor indoor humidity levels

Seasonal use (summer house, country home)

Specifics:

- The pool and dehumidifier are only used during a certain season

- Long idle periods

- Higher risk of mold with improper storage

Recommendations:

- Before a long shutdown, run ventilation mode for 2–3 hours

- Clean all filters before storage

- Check and clean before the new startup

- If possible, leave it running at minimal power

FAQ: answers to the most common questions

1. Can mold grow inside an MSHA(C) dehumidifier?

Yes, mold can grow in any dehumidifier if maintenance rules aren’t followed. Mold most often appears in filters (if they’re dirty and wet), in the condensate pan (if water stagnates), and on the heat exchanger (if it isn’t cleaned). MSHA(C) models have multiple layers of protection: positive-pressure drainage, a stainless pan, and the option to install a UV lamp. But regular filter cleaning is still mandatory.

2. How often do filters need cleaning in MSHA(C)?

The G4 (coarse) filter should be cleaned every 2–4 weeks, the F7 (fine) filter — every 1–2 months, and the HEPA H13 filter should be checked every 6–12 months with replacement every 2 years. Frequency depends on air cleanliness and pool usage intensity.

3. What happens if I don’t clean the filters?

Clogged filters reduce dehumidifier performance by 30–50%. The compressor runs overloaded, consuming more electricity. Mold can develop in the filters themselves, causing unpleasant odors. As a result, the dehumidifier’s service life drops from a potential 10–15 years to just 3–5 years.

4. How do I know it’s time to clean the filters?

Main signs: room humidity doesn’t drop to a comfortable 55%, the dehumidifier has become louder, a musty odor has appeared, and visible contamination is seen during a visual inspection.

5. Can I clean the filters myself, or do I need service?

The G4 and F7 filters can and should be cleaned by the owner. It’s simple: remove, vacuum or rinse, dry completely, reinstall. The HEPA H13 filter is typically just replaced with a new one every 2 years. Heat exchanger cleaning, however, is best left to a service team with the proper equipment and agents.

6. Why does the dehumidifier smell bad?

Possible reasons include: mold in dirty filters, standing water in the pan due to drainage problems, mold on the heat exchanger if there hasn’t been service for a long time, or a dirty water trap. The solution: clean the filters, check the drainage, and if that doesn’t help — call a service team.

7. Do I need a UV lamp for mold protection?

For residential pools, a UV lamp is desirable but not mandatory if regular maintenance is provided. For commercial facilities, it’s strongly recommended as additional protection for clients. A UV lamp effectively destroys mold spores, bacteria, and viruses in the air passing through the dehumidifier.

8. How often is professional service required for MSHA(C)?

For residential pools, professional service is recommended every 1–2 years; for commercial facilities — annually. Service includes heat exchanger cleaning, refrigerant checks, UV lamp replacement (if installed), and a full systems check. Regular maintenance extends equipment life to 15 years or more.

9. What should I do if the dehumidifier is shut down for the winter?

Before a long shutdown: 1) clean the filters; 2) run ventilation mode without cooling for 2–3 hours to dry internal elements; 3) only then turn the unit off. In spring, before turning it on, check and clean the filters. Ideally, keep the dehumidifier running at minimum power even in an unused space.

10. Is mold in a dehumidifier dangerous to health?

Yes, mold in a dehumidifier poses a real health hazard. Since the dehumidifier constantly circulates air throughout the pool area, mold spores spread and can cause allergic reactions and respiratory problems, especially in children and people with asthma. Therefore, regular maintenance is critical to maintaining a healthy indoor climate.

Technical specifications of MSHA(C) models

| Model | Dehumidification capacity (L/day) | Airflow (m³/h) | Power input (W) | Noise level (dB) | Filters |

|---|---|---|---|---|---|

| MSHA(C) 28 | 28 | 280-350 | 420 | <35 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 40 | 40 | 500-670 | 670 | <45 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 60 | 60 | 650-780 | 740 | <45 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 100 | 100 | 1000-1200 | 1050 | <45 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 140 | 140 | 1200-1350 | 1300 | <45 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 180 | 180 | 1800-2200 | 3000 | <55 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 250 | 250 | 2500-2900 | 4200 | <55 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 380 | 380 | 3500-3850 | 6600 | <55 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 500 | 500 | 4800-5300 | 10000 | <55 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 750 | 750 | 7500-9000 | 17000 | <55 | G4+F7 (+HEPA H13 option) |

| MSHA(C) 1000 | 1000 | 9000-11000 | 23500 | <55 | G4+F7 (+HEPA H13 option) |

Note: MSHA(C) 28–60 models use refrigerant R134A, and MSHA(C) 100–1000 — R410A. All models are equipped with an SUS304 stainless-steel condensate pan and a heat exchanger with hydrophobic Blue Coating.

Conclusion

Mold can develop in a dehumidifier, but with proper care it’s easy to avoid. MSHA(C) dehumidifiers are designed with six levels of mold protection: an effective positive-pressure drainage system, an SUS304 stainless-steel pan, hydrophobic Blue Coating on the heat exchanger, three-stage filtration, the option to install a UV lamp, and continuous air circulation.

But even with such a robust design, regular maintenance remains the key factor in preventing mold. The most important procedures are cleaning the G4 filter every 2–4 weeks, checking the drainage once a month, and professional service every 1–2 years. With this approach, the dehumidifier’s service life will be 10–15 years or more, and the air in your pool area will always be clean and healthy.

For more information, you can download a detailed MSHA(C) maintenance manual in PDF from our website. We also offer initial technical maintenance during which our specialists will show you how to properly clean the filters in your model. For maximum convenience, we recommend signing a service agreement — we will remind you about necessary cleanings and perform annual maintenance.

Use the feedback form at the bottom of the page to contact us or call the phone number provided.