-

Poland – Polski

-

Lithuania – Lithuanian

-

Netherlands – Dutch

-

Denmark – Danish

-

Estonia – Estonian

-

Finland – Finnish

-

France – French

-

Greece – Greek

-

Italy – Italian

-

Latvia – Latvian

-

Portugal – Portuguese

-

Romania – Romanian

-

Slovenia – Slovenian

-

Spain – Spanish

-

Austria – German

-

Germany – German

-

Switzerland – German

-

Czech Republic– Czech

-

Sweden – Swedish

-

Liechtenstein – German

-

Slovakia – Slovak

-

Ukraine – Ukrainian

-

Moldova – Romanian

-

Cyprus – Greek

-

Ukraine – Russian

-

Croatia – Croatian

-

Bulgaria – Bulgarian

-

Malta – English

Water chiller MWU series

Want to buy or have questions?

Eco-friendly water-cooled chillers of MWU series offered by Mycond are the right fit for facilities where the installation area is small, or the outdoor unit must be installed distantly.

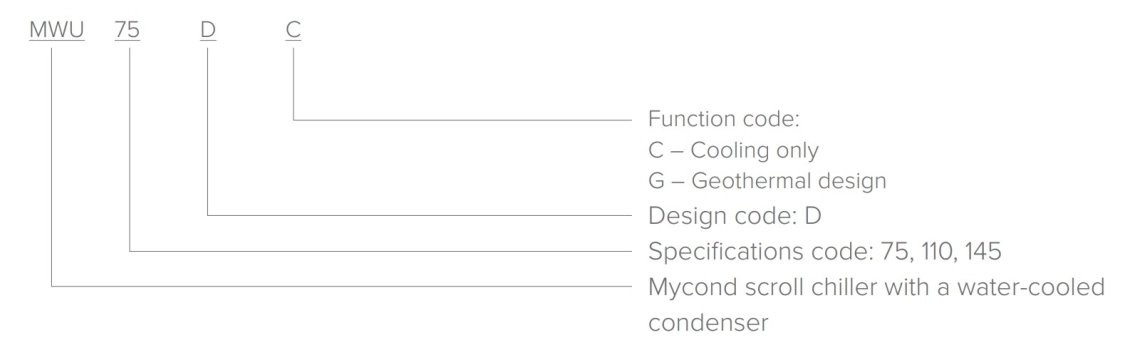

Designation

Compressor

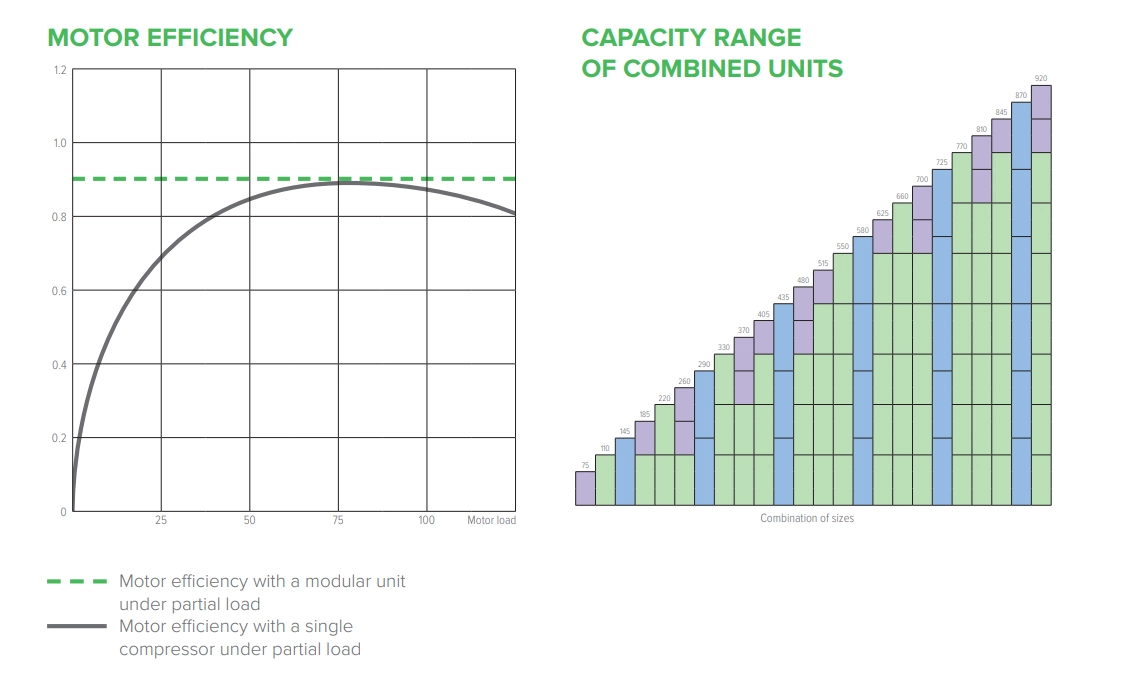

High efficiency scroll compressors are used in this unit. This type of compressor has impressive capacity, low friction losses and high operating efficiency. Each modular unit is equipped with two scroll compressors. By combining several modules into a single system, you can control the capacity in several stages, which will be more energy efficient under partial load.

Condenser and evaporator

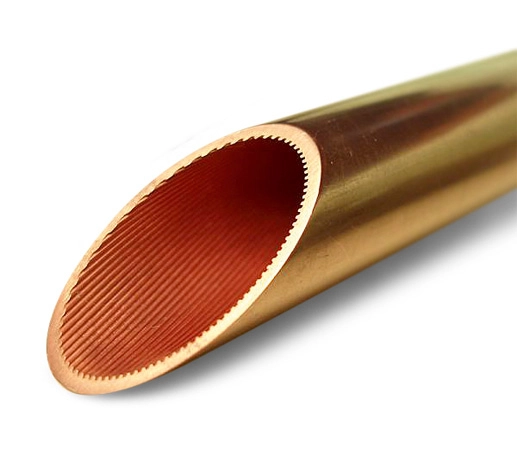

The unit uses high-efficiency shell-and-tube heat exchangers made of copper tubes with grooved inner surface, which means more efficient heat transfer thanks to more turbulent refrigerant flow. The increased surface area reduces temperature drop during the heat exchange, while improving the EER. The condenser has a subcooler in the lower part for better subcooling of liquid refrigerant. The heat exchangers are rigorously tested for defects, as well as pressure tested for leaks, to ensure safety and reliability.

Cooling accessories

The electronic expansion valve and all the protective controls used in the units are provided by world-famous manufacturers, which means proven quality and longterm stable operation.

Intelligent control

The unit has a user-friendly interface for various operating needs. With microcomputer-based monitoring, the unit implements various functions, such as temperature control, time setting, data recording, status display, alarm output, temperature setting and group control.

Modular design for improved energy efficiency

Each individual module offers 2-step capacity control. Combination of modules gives more flexibility in capacity control. The intelligent compressor balancing improves the system efficiency at small loads and saves the energy for continuous operation. Failure of one module does not affect other modules. The modules can be combined in different ways and controlled independently.

Numerous protection features

Stable operation of an air conditioner is critical for industrial and commercial users. The eco-friendly watercooled scroll chiller (heat pump) by Mycond has passed long-lasting tests at even stricter conditions than required by the national standard. The results of testing exceed the national standard. The unit is equipped with numerous protections that ensure normal operation, long service life and safety.

- Phase sequence protection

- Compressor stop-start protection

- Compressor overload protection

- Discharge temperature protection

- High and low pressure protection

- Phase loss protection

- Automatic freeze protection

- Automatic alarm and reset for some faults

- Automatic loading and unloading

- Powerful external interlock

Specifications of a cooling only unit

| Specifications | Units | MWU 075 DC | MWU 110 DC | MWU 145 DC |

| Cooling capacity | kW | 74,4 | 112,2 | 146,3 |

|

Input power EER |

kW W/W |

14,9 5 |

22,4 5 |

29,2 5 |

| Number of compressors | 2 | 2 | 2 | |

| Capacity steps | % | 0/50/100 | 0/50/100 | 0/50/100 |

| Water pipe diameter in the shell-and-tube evaporator | DN 50 | DN 50 | DN 65 | |

| Water flow rate in the shell-and-tube evaporator | m3/h | 12,8 | 19,3 | 25,2 |

| Water pressure drop in the shell-and-tube evaporator | kPa | 39 | 47 | 60 |

| Connection method in the shell-and-tube evaporator | Flexible clamp | Flexible clamp | Flexible clamp | |

| Water pipe diameter in the shell-and-tube condenser | DN 65 | DN 65 | DN 80 | |

| Water flow rate in the shell-and-tube condenser | m3/h | 16,0 | 24,1 | 31,5 |

| Water pressure drop in the shell-and-tube condenser | kPa | 24 | 48 | 82 |

| Connection method in the shell-and-tube condenser | Flexible clamp | Flexible clamp | Flexible clamp | |

| Compressor type | Hermetic scroll compressor | Hermetic scroll compressor | Hermetic scroll compressor | |

| Start method | Direct start | Direct start | Direct start | |

| Maximum operating current, А | 48 | 71,9 | 95,8 | |

| Dimensions, L x W x H | mm | 1880×660×1380 | 1880×660×1490 | 1880×740×1590 |

| Refrigerant type | R410A | R410A | R410A | |

| Number of cirquits | 2 | 2 | 2 | |

| Control method | Electronic expansion valve (EXV) | Electronic expansion valve (EXV) | Electronic expansion valve (EXV) | |

| Refrigerant charge | kg | 12 | 14,5 | 18 |

| Lubricant | POE | POE | POE | |

| Packed weight | kg | 470 | 520 | 630 |

| Operating weight | kg | 500 | 555 | 670 |

Notes:

1. The above data have been obtained at the rated operating conditions: inlet/outlet chilled water temperature 12/7 °C; inlet/outlet cooling water temperature 30/35 °C.

2. Power supply: 380 V, 3 + N, 50 Hz; voltage tolerance: ±10%.

3. For other associated unit parameters, contact the supplier.

4. The unit specifications can be changed without prior notice for the purpose of improvement.

| Specifications | Units | MWU 075 DG | MWU 110 DG | MWU 145 DG |

| Cooling capacity | kW | 75,6 | 113,4 | 149,2 |

| Heating capacity | kW | 81,2 | 121,2 | 154,2 |

|

Input power in the cooling mode EER |

kW W/W |

13,7 5,52 |

20,5 5,53 |

27,1 5,5 |

|

Input power in the heating mode COP |

kW W/W |

18,3 4,44 |

28,1 4,3 |

36 4,3 |

| Number of compressors | 2 | 2 | 2 | |

| Capacity steps | % | 0/50/100 | 0/50/100 | 0/50/100 |

| Water pipe diameters on the cold and hot water sides | DN 50 | DN 50 | DN 65 | |

| Water flow rate on the cold and hot water sides | m3/h | 13 | 19,5 | 25,7 |

| Water pressure drop on the cold and hot water sides | kPa | 40 | 48 | 63 |

| Connection method on the cold and hot water sides | Flexible clamp | Flexible clamp | Flexible clamp | |

| Water pipe diameters on the side of ground water circuit | DN 65 | DN 65 | DN 80 | |

| Water flow rate on the side of ground water circuit | m3/h | 16,3 | 24,4 | 32,1 |

| Water pressure drop on the side of ground water circuit | kPa | 25 | 50 | 87 |

| Connection method on the side of ground water circuit | Flexible clamp | Flexible clamp | Flexible clamp | |

| Compressor type | Hermetic scroll compressor | Hermetic scroll compressor | Hermetic scroll compressor | |

| Start method | Direct start | Direct start | Direct start | |

| Maximum operating current, А | 48 | 71,9 | 95,8 | |

| Dimensions, L x W x H | mm | 1880×660×1380 | 1880×660×1490 | 1880×740×1590 |

| Refrigerant type | R410A | R410A | R410A | |

| Number of cirquits | 2 | 2 | 2 | |

| Control method | Electronic expansion valve (EXV) | Electronic expansion valve (EXV) | Electronic expansion valve(EXV) | |

| Refrigerant charge | kg | 12 | 14,5 | 18 |

| Lubricant | POE | POE | POE | |

| Packed weight | kg | 470 | 520 | 630 |

| Operating weight | kg | 500 | 555 | 670 |

Recommended concentration of glycol solution:

| Outlet water temperature, °C | Recommended mass fraction, % |

| 0 – 3 | 20 |

| -5 – 0 | 25 |

| -10 – -5 | 35 |

Notes:

1. The above data have been obtained at the rated operating conditions:

Cooling mode: inlet/outlet chilled water temperature 12/7 °C; inlet/outlet geothermal water temperature 25/30 °C.

Heating mode: outlet hot water temperature 45 °C; inlet geothermal water temperature 10 °C.

2. If the outlet geothermal water temperature is below 3 °C, add glycol solution to the water. For details, see table “Recommended concentration of glycol solution”.

3. Power supply: 380 V, 3 + N, 50 Hz; voltage tolerance: ±10%.

4. For other associated unit parameters, contact the supplier.

5. The unit specifications can be changed without prior notice for the purpose of improvement.